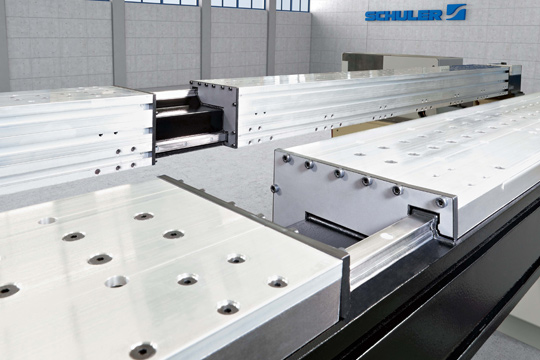

THE INTRA TRANS TRANSFER

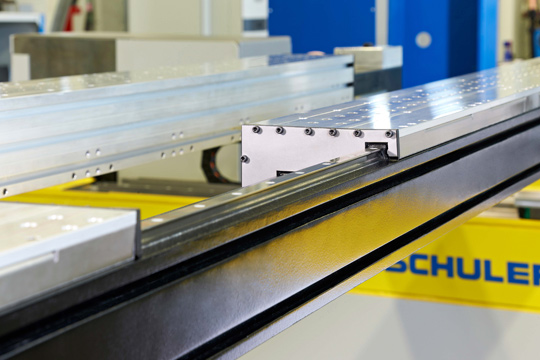

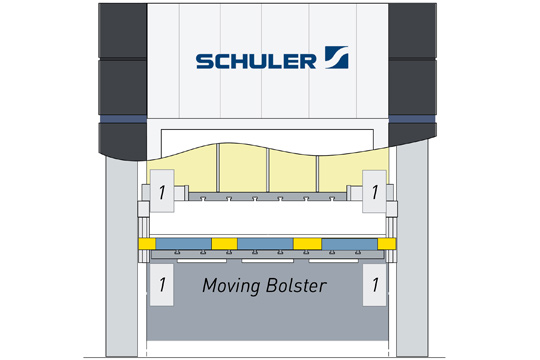

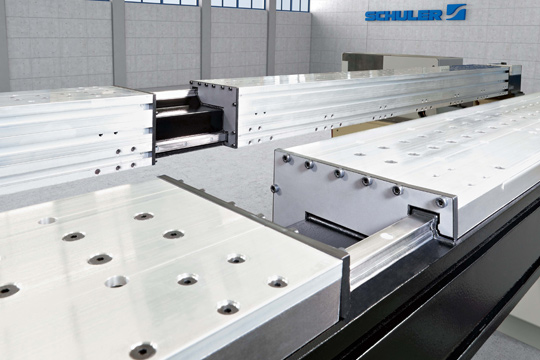

In the case of Intra Trans, the transfer rails are located between the press uprights, so that the coil width is maximized. The die space remains free – as a result, the entire width of the press can be utilized.

In the case of Intra Trans, the transfer rails are located between the press uprights, so that the coil width is maximized. The die space remains free – as a result, the entire width of the press can be utilized.

Various die stages and the feed of materials can be implemented with Intra Trans in and against the direction of flow. Due to the U-shaped travel, several work steps can be performed with one die.

In the case of Intra Trans, the clamping box can be attached above or below the feed level – various positions on the entry and exit side are possible with this model.

The high degree of flexibility contributes to better planning in engineering, as well as economic efficiency when retrofitting existing presses. Progressive die presses can also be retrofitted without limitation.

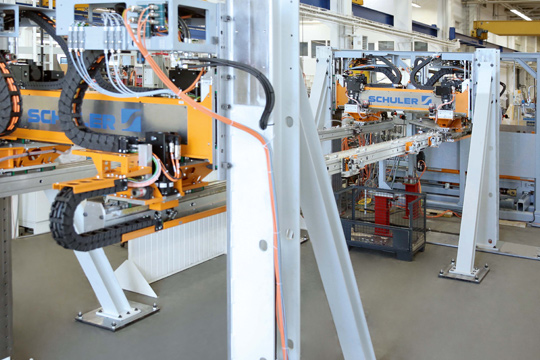

Asynchronous movement profiles, selectable clamping box positions and three synchronized, programmable axes – best adaptability for all ...

Read More

Independent carriage movements allow for different increments – thanks to an integrated feed axis in a particularly compact design.

Read More

Maximum loading and high degree of automation? The combination leads quickly to a swing-up of the machine. To prevent a reduction of the motor ...

Read More

In the area of transfer systems, you are safe with Schuler: Our automation solutions offer reliable production processes at economic conditions for all requirements. Whether a wide range of parts, high production rate or low spatial requirement – equip existing systems with Schuler transfer solutions and increase the production rate.

Find out more about the transfer solutions of Schuler – all highlights on this page.

Bernhard Köhler

Head of Regional Sales Europe

location_on Louis-Schuler-Straße 1, 91093 Heßdorf phone +49 9135 715-317 mail_outline E-Mail

Berthold Jüttner

Sales Manager

location_on Louis-Schuler-Straße 1, 91093 Heßdorf phone +49 9135 715-218 mail_outline E-Mail

Justine Fonteyne

Area Sales Manager North & South America

location_on Louis-Schuler-Str. 1, 91093 Heßdorf phone +49 9135 715-387 mail_outline E-Mail