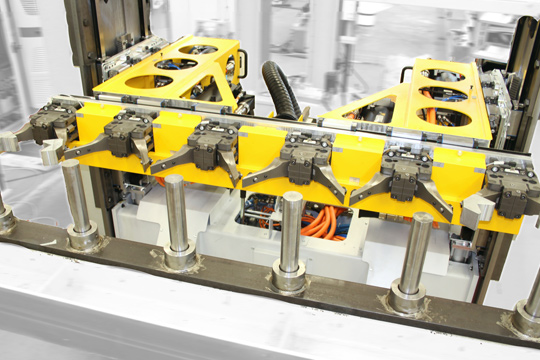

ACTIVE ANTI-VIBRATION SYSTEM (AVD)

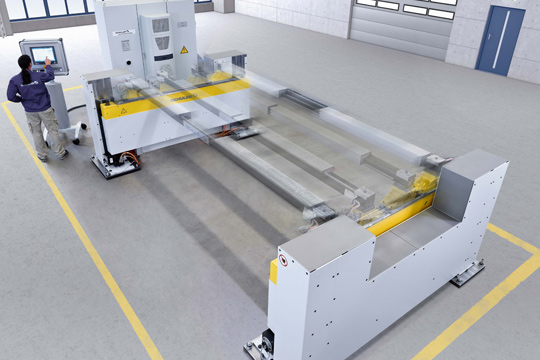

The maximum load and high degree of automation can lead to high vibration amplitudes of the transfer rails. To guarantee problem-free, reliable parts transportation, it is often necessary to reduce the motor output – which slows down production – or increase the transfer rail profiles.

The active anti-vibration system reduces vibration amplitudes to ensure the maximum speeds and throughput rates of the production line.

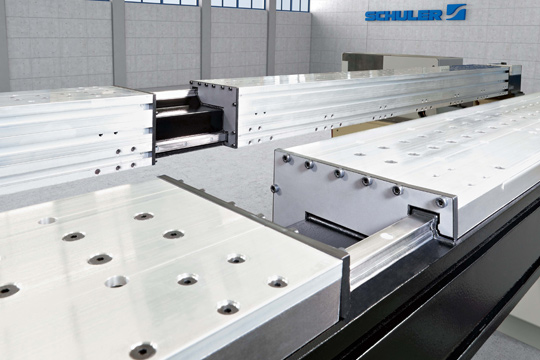

This enables the use of smaller transfer profiles at the same output.

With the exclusive, active anti-vibration system (AVD), Schuler guarantees a vibration amplitude of less than a millimeter at maximum load and maximum speed of the parts transportation process.

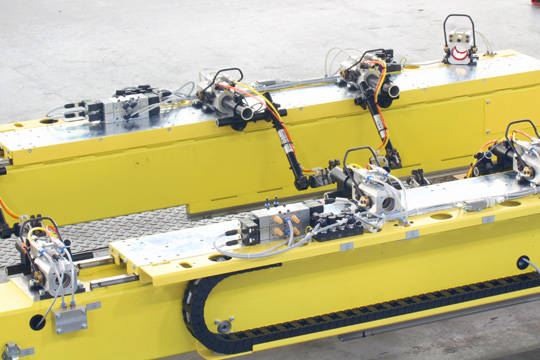

FLEXIBLE MODULAR SYSTEM

- The electronic overload protection of the transfer system guarantees a safe shutdown and the axis do not have to be calibrated

- 4-point and 6-point support offer maximum rigidity of the rail and a safe transportation of the components, even at maximum speeds

- The active anti-vibration system (AVD) permits the maximum achievable positioning precision

- Asynchronous movement profiles for maximum flexibility for component movement and the design of the dies

Your advantages:

- INCREASE in production rates

- IMPROVEMENT of productivity

- CONSISTENT reduction of piece price

MAINTENANCE AND AVAILABILITY

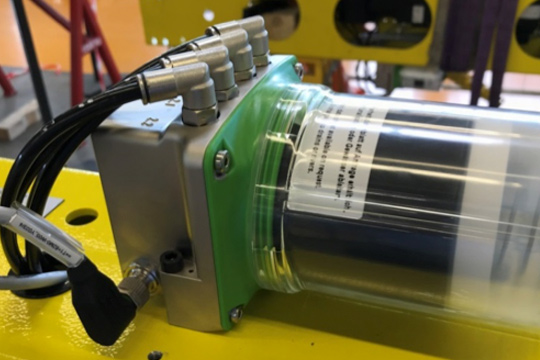

- Bearings with lifetime lubrication

- Long-term lubricating units in sheet-metal forming and central lubrication system in forging

- Number of limit switches reduced to a minimum

- Maintenance and spare parts available worldwide

- Same servo motors and frequency converters on all axes

Your advantages:

- MAXIMUM availability of the system

- FAST AND EASY maintenance

- CONSIDERABLY REDUCED maintenance costs and spare parts stock

TRANSFER SYSTEMS FOR SHEET-METAL-FORMING

A new modular transfer system generation from Schuler is a high-performance supplement to presses used in sheet-metal forming …

Read More

TRANSFER SYSTEMS FOR FORGING

Schuler automation solutions are perfectly adapted to the environmental conditions for cold, warm and hot forging ...

Read More

TRANSFER SYSTEMS FOR MULTI-SLIDE PRESSES

By extra carriage: transport without intermediate storage. Minimal set-up at maximum production capacity. The programmable axes ensure...

Read More

Bernhard Köhler

Head of Regional Sales Europe

location_on Louis-Schuler-Straße 1, 91093 Heßdorf phone +49 9135 715-317 mail_outline E-Mail

Berthold Jüttner

Sales Manager

location_on Louis-Schuler-Straße 1, 91093 Heßdorf phone +49 9135 715-218 mail_outline E-Mail

Justine Fonteyne

Area Sales Manager North & South America

location_on Louis-Schuler-Str. 1, 91093 Heßdorf phone +49 9135 715-387 mail_outline E-Mail