THE INTRA FEED TRANSFER

With Intra Feed, Schuler offers all advantages of Pro Trans, while setting new standards in regard to flexibility.

With Intra Feed, Schuler offers all advantages of Pro Trans, while setting new standards in regard to flexibility.

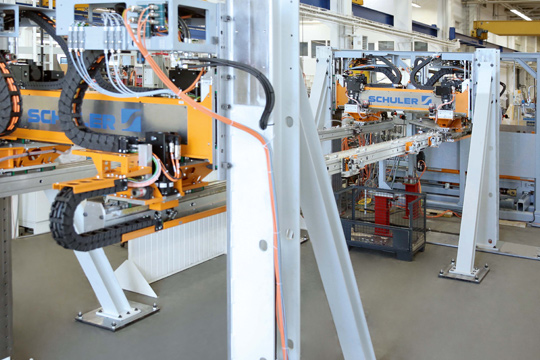

The carriage movements, which can be programmed independently from each other make different increment distances possible within a press. Due to the U-shaped travel, several work steps can be performed with one die.

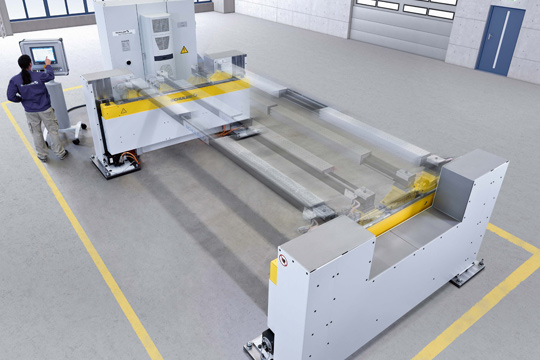

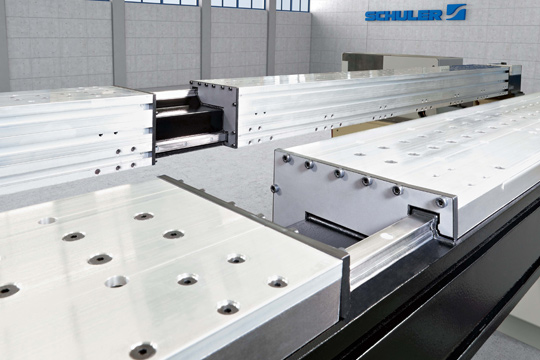

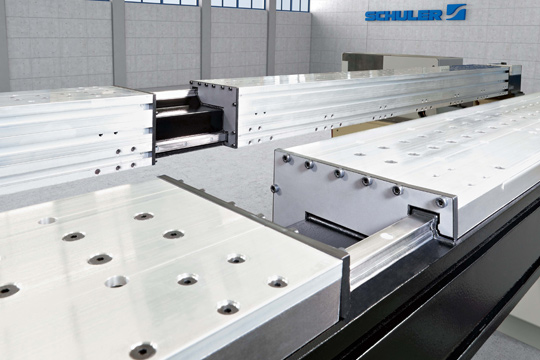

Thanks to the feed axis integrated into the transfer rail, the system length is shortened considerably. In the case of the upstream coil line, the residual coil (Maybe: tail-out) can be considerably reduced – with simultaneously increased feed precision.

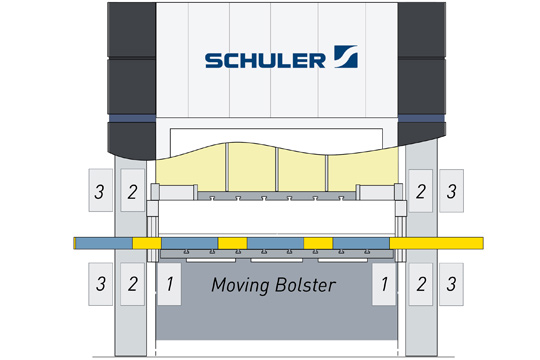

The selectable positions for the clamping boxes on the inside and outside and between the press upright depend on the flexibility of Intra Feed.

With the development of the TwinServo technology, Schuler has literally turned press technology upside down: drive units were moved from the crown to the press bed. In addition, the new press concept is characterized by two mechanically separated drives that open completely new possibilities. These changes result not only in several advantages for the forming process, but also for noise emissions, spatial requirement, hall height, etc.

We need your consent to load content.

In order to show videos we use the services of third-party providers. These providers can collect data about your activities. Further details can be found under “Learn more”.

Asynchronous movement profiles, selectable clamping box positions and three synchronized, programmable axes – best adaptability for all ...

Read More

Less is sometimes more: as transfer rails are not required, the maximum material width can be processed between the press uprights. ...

Read More

Maximum loading and high degree of automation? The combination leads quickly to a swing-up of the machine. To prevent a reduction of the motor ...

Read More

In the area of transfer systems, you are safe with Schuler: Our automation solutions offer reliable production processes at economic conditions for all requirements. Whether a wide range of parts, high production rate or low spatial requirement – equip existing systems with Schuler transfer solutions and increase the production rate.

Find out more about the transfer solutions of Schuler – all highlights on this page.

Bernhard Köhler

Head of Regional Sales Europe

location_on Louis-Schuler-Straße 1, 91093 Heßdorf phone +49 9135 715-317 mail_outline E-Mail

Berthold Jüttner

Sales Manager

location_on Louis-Schuler-Straße 1, 91093 Heßdorf phone +49 9135 715-218 mail_outline E-Mail

Justine Fonteyne

Area Sales Manager North & South America

location_on Louis-Schuler-Str. 1, 91093 Heßdorf phone +49 9135 715-387 mail_outline E-Mail