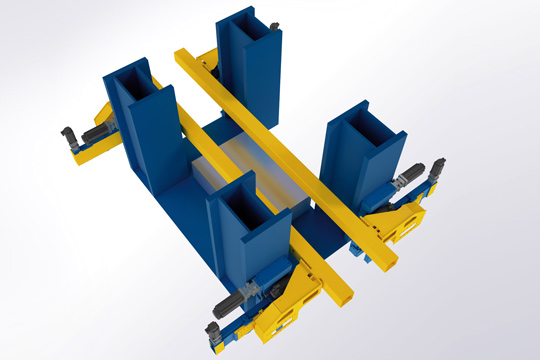

THE DOUBLE BEAM TRANSFER

With Double Beam, Schuler offers a special transfer unit that can be used in both cold and hot forming.

With Double Beam, Schuler offers a special transfer unit that can be used in both cold and hot forming.

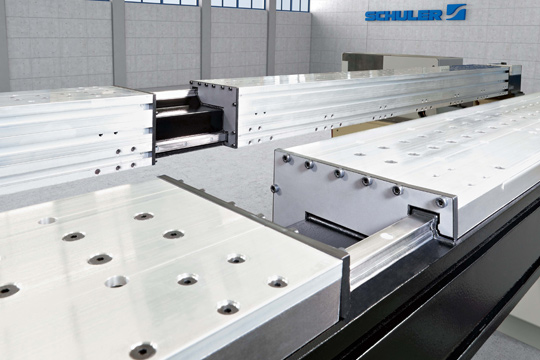

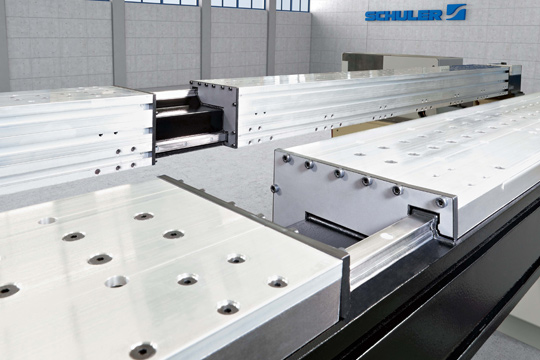

Four clamping boxes and high-quality protection against damage from the rough environmental conditions during forging guarantee maximum reliability and production throughput: Heat, lubricants or coolants have no adverse effects on rails or clamping boxes.

Parts transportation and clamping of the components are implemented using two transfer rails, whereby parts handling is executed using passive grippers.

The die change procedure is particularly easy due to the large stroke: the transfer rails do not have to be removed for individual die changes.

The compact and streamlined structure simplifies the planning in feeding of the material and to convey the parts out. Thanks to the protective devices and use of stainless steel, the maintenance effort is reduced to a minimum. Maximum production rate due to transfer rails with 4-point supports and Schuler AVD.

The modular construction and easy die change simplify operation.

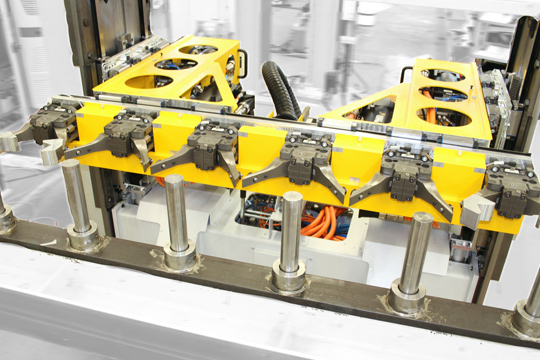

Weight-optimized, compact and precise special transfer for cold forming. Parts handling unit with active hydraulic gripper for maximum ...

Read More

Reliability and with reduced number of components: The Mono Beam is particularly economical. Example: Die change without removal of the...

Read More

Maximum loading and high degree of automation? The combination leads quickly to a swing-up of the machine. To prevent a reduction of the motor ...

Read More

In the area of transfer systems, you are safe with Schuler: Our automation solutions offer reliable production processes at economic conditions for all requirements. Whether a wide range of parts, high production rate or low spatial requirement – equip existing systems with Schuler transfer solutions and increase the production rate.

Find out more about the transfer solutions of Schuler – all highlights on this page.

Bernhard Köhler

Head of Regional Sales Europe

location_on Louis-Schuler-Straße 1, 91093 Heßdorf phone +49 9135 715-317 mail_outline E-Mail

Berthold Jüttner

Sales Manager

location_on Louis-Schuler-Straße 1, 91093 Heßdorf phone +49 9135 715-218 mail_outline E-Mail

Justine Fonteyne

Area Sales Manager North & South America

location_on Louis-Schuler-Str. 1, 91093 Heßdorf phone +49 9135 715-387 mail_outline E-Mail